We commit ourselves to meeting the most demanding requirements of our customers and continually improve their quality in accordance with the STN EN ISO 9001: 2015 standard.

We offer many years of experience and creativity in engineering solutions. We offer our customers cost-effective and innovative solutions.

01

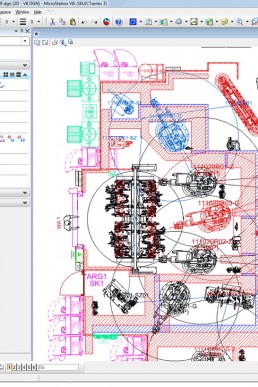

Planning

Robot line concept processing

The Planning Department is engaged in designing robotic line concepts and designs from small parts up to planning the whole production.

- Feasibility studies

- Process planning

- Layout planning with comprehensive processing of production operations and production tools layout

- Ergonomics

- MTM time analysis for manual workplaces

- Time cycle analysis

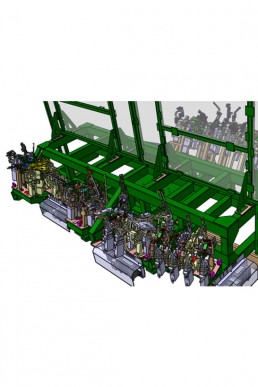

Design

Schemes for robotic line jigs

The Design Department is dealing with complex designs of robotic line jigs, always trying to offer simple and cost-effective solutions.

- Clamping devices both automatic and manual for:

- Spot welding

- Riveting

- Screw welding

- Sheet metal bonding by Clinchen

- Mounting systems for different products

- Handling equipment robotic, hand, motorized, etc.

- Measuring and control jigs

- Conveyor technology

- Testing jigs

- Clamping concepts, 3D / 2D construction and BOMs

02

03

Simulation

Creation of robotic and manual workplaces

The simulation department deals with the creation of robotic and manual workplaces according to customer requirements.

- Timing test

- Constructive implementation of planning results

- Choosing the right tools

- Selection of suitable robots

- Availability and feasibility testing

- Examination of suitable placements of robots and jigs with respect to time

Applications:

- Spot welding

- MIG welding

- Stud welding

- Clinching method for sheets joining

- Gluing/ Bonding

- Measuring surfaces using cameras (ISRA)

- Handling processes

- Feeding processes

Off-line programming

Development of off-line programs for robots

The off-line robot programming department is engaged in the creation, implementation and optimization of off-line robot programs.

- Creating OLP programs for ABB, Fanuc, Kuka robots

- Examination of the load data (Examination of the tool weight for the axis (engines) of the robot (s)

- Measuring the robot base relative to the jig, station, and the like

- Upload and run offline programs

- Online programming

- Optimization of individual programs

- Optimization of batches

- Production escort for opening up the lines

- Training maintenance personnel

- Documentation for an individual robot or line

04

05

Documentation

Documentation for robotic links

The Documentation Department is involved in the production and delivery of relevant multi-lingual documentation (EN / DE / CZ / SK)

- Overall layout

- BMS description

- Overview of the joining sequences parts

- Schedule and activities of MTM analysis

- Spot welding plans

- Pneumatic plan and BOMs of pneumatic parts

- Media plans

- Plans of functions

- Time schedules

- Maintenance and repair plan

References

We offer our partners comprehensive and innovative solutions in industrial automation as well as in the automotive sector.

Audi

- AU 37x / Outside sidewall framing

- AUDI S1 / Sub frames, Fixture devices for MIG welding

- AU 736 / Rear ending piece

- AU 736 / Concept for A-Pillar, rear inside wheelhouse, door sill board

- AU 49x / Rear floor integration, rear floor N60 (new development)

- AU 426 / Engine hood

- AU27x / Front doors, rear doors

BMW

- F34/F36 / rear floor

Ford

- Ford Otosan V362 / Front doors, Sliding doors, Cargo doors

- Ford Otosan V363 / Front doors, Sliding doors, Cargo doors

Jaguar Land Rover

- X540 / Assembly line

Lamborghini

- URUS – rear floor, roof, rear inside wheelhouse, rear ending piece

Daimler

- DC W246/C117 / Z1 Underbody, Z2 Inside sidewall, Rastatt-Kecskemet

- Smart BR 453 / Inside sidewall, outside SW, underbody

- BR 205 / roof, C-pillar

- BR 253 / roof, C-pillar

- BR 238 / roof, C-pillar

Porsche

- PO536 / Underbody, rear inside wheelhouse

Scania

- LE & Crew cabine doors

Seat

- SE38x / Front doors, Rear doors

- SE316 / Front doors, Rear doors

Skoda

- SK 341 / Mounting fixture devices for front door, back door, engine hood, and hatch door

- SE 376 / Front floor, tunnel

- SK 376 /1 / Front floor, tunnel

- SK 326 / integration, Underbody

- SK 370 / Front floor+Tunnel / Front wall+UB2

Tesla

- Model 3 / Underbody

Volkswagen

- VW Hannover T5 / Longitudinal chassis beam

- VW 361 / Inside sidewall, rear, A-Pillar inside bottom

- VW 481 CN / Outside sidewall

- VN 54x / Underbody

- VW 38x / Front floor, Underbody 2, Longitudinal beam L/R

Volvo

- Volvo V526 / Rack Changers, rear underbody

- Volvo S/E PROJECT / concept study

- Volvo L541 / doors

Capacity

Our annual capacity in engineering solutions reaches 165,000 hours.

... in cooperation over 250,000 hours.

Planning

Off-line programming

Simulation

Construction